Making

The making team at Nelson Packaging Company has over 40 years of making experience, including partnership with a Fortune 500 company, in delivering new products to market. We offer blending and compounding services including chemical process engineering and design. Our skilled team is experienced in making bulk product from raw materials as well as the ability to finish your base product with minor additions.

Nelson provides effective blending and filling systems including but not limited to: meeting your specifications on formulations, equipment operations under optimum conditions, and tight quality management practices to ensure superior quality and customer satisfaction.

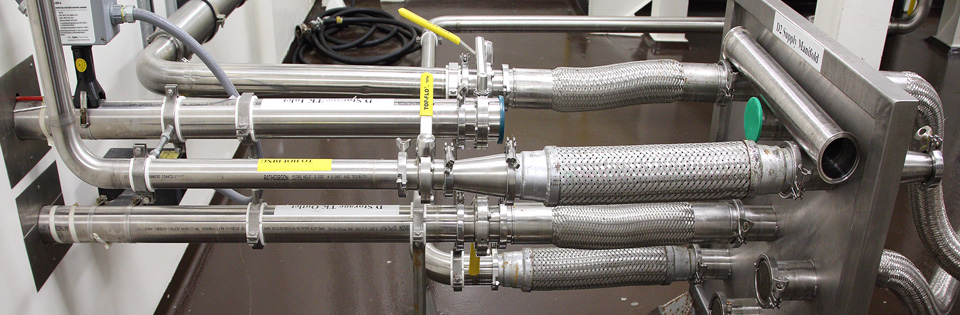

Our manufacturing process utilizes an automated system with the blending tanks mounted on load cells and flow meters to manage and control the addition of raw materials. Raw materials are precisely monitored to account for traceability and are stored in temperature controlled tanks under N2 blanketing.

Our liquid/blending systems include batch mixers and continuous process systems. The equipment includes two sanitary design mixers – one 5,000 gallon and one jacketed 2,500 gallon unit – housed in a controlled, clean room environment. The 2,500 jacketed unit has the ability to heat and cool materials during the blending process to meet your specifications. In addition, several small mix tanks are available for pilot and development batches. Finally, there are three 5,000 gallon agitated cold mix tanks available to blend non-micro susceptible products. Supporting these systems are our tank farms – offering over 20 storage tanks for raw materials and finished products.

Whether you need to rapidly satisfy an increase in demand or are looking to outsource the manufacture of a new formulations, Nelson Packaging Company has your solution. Contact us today to see how our full turnkey blending and filling operation can help you achieve your goals.

| General Capabilities: | ||

|---|---|---|

| Blending Capacity |

|

|

| Packaging Capabilities |

|

|

| In-House Services |

|

|

| Quality Control Procedures |

|

|

| Environmental Sustainability |

|

|

| Raw Materials Used |

|

|

| Industries Served |

|

|